☏ +91 961-844-9701 ✉ info@JKtilemachinery.co.in

Concrete Pan Mixture CMS -300

- Durable chill cast wear sleeves and paddles

- Hard wearing chill cast tiles for wall and floor

- Heavy-duty discharge door mechanisms

- Full-welded frames, making them more stable over time

- The mixing tray is also full-welded

Major Components of JK-CMS300

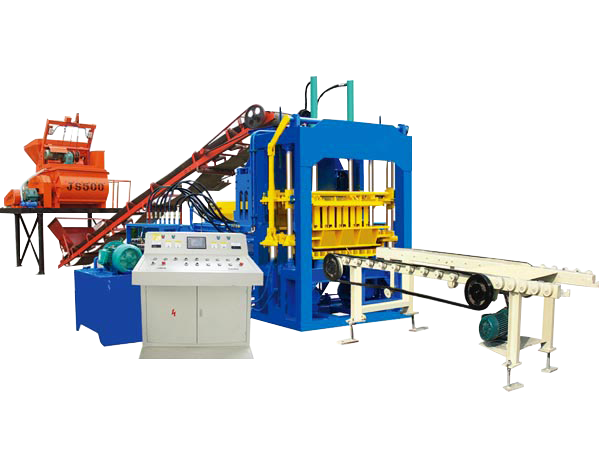

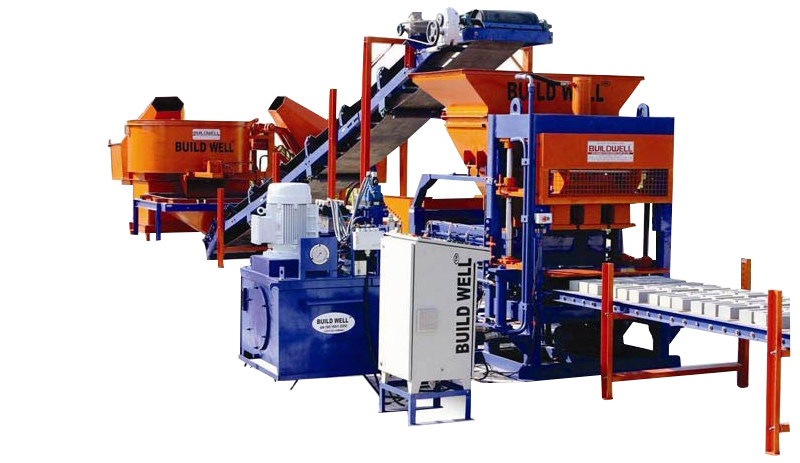

Cement Tiles Making Machine

Paver Tiles Making Machine

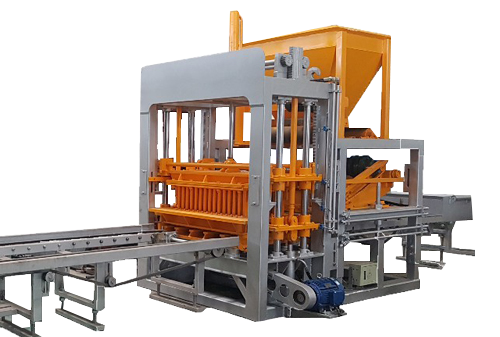

Paving Block Making Machine

Hollow Block Making Machine

Vibrating Table Machine

Manual Hydraulic Paving Block Making Machine

Technical Specification

| No. | JK-VIBMAX-1025 | Technical Data |

|---|---|---|

| 1 | Overall Dimension | 89"x45"x60" (In Inches) Approx |

| 2 | Total Power | 5 Hp ,SGL. Motors© Brand |

| 3 | Batch Capacity | Batch Capacity 300 Kgs.(Maximum)s |

| 4 | Sheet Thickness | 8 MM Top Sheet Thickness/ Bottom Plate 12 MM/Side Plate 8 MM |

| 5 | Cycle Time | 6 | Power Supply | 3 Phase 440 volts commercial Connection |

| 7 | Maximum Block Height | Variable Depends On Product |

| 8 | Automation Grade | Semi Automatic + Manual |

| 9 | End Production Type | Used In Back Layer Concrete Layer Mixing Or Manufacturing Of Wide Variety Of Cement Tiles, Paver Block And Designer Tiles. |

Actual Site Image Of Some Completed Projects

Application Area and Field Completed Projects